From Design to Prototype – Precision, Speed & Confidentiality. one-stop prototype solutions manufacturing for hardware innovators.

- CNC Machining (Aluminum / Stainless Steel / Engineering Plastics)

- Plastic Injection Molding

- Urethane Casting (PU / Silicone)

- Printing (SLA / SLS / MJF / FDM)

- Sheet Metal Fabrication

- Surface Finishes & Coatings

Golden Rapid, founded in June 2013. It was born from the desire to offer the Italian market solutions in terms of design, prototyping and creation of components through engineering know-how gained over the years.

Full Industry Chain Coverage

Prototype components and small series, Precisely manufactured, quickly delivered.

From concept sketches and CAD drawings to high-quality prototypes and low-volume production, our experienced team ensures:

Core Value

- Confidentiality under strict NDA

- High-precision machining & advanced surface finishing

- Cost-effective, fast delivery cycles

- Scalable transition from prototype to injection molding

With strict confidentiality, fast lead times, and reliable quality, Golden Rapid helps you turn ideas into functional prototypes and scalable production.

Our diverse manufacturing technologies and quality management offer the best prerequisites for realisation.

Whether you are developing smart wearables, optical modules, charging solutions, or next-gen entertainment devices, Golden Rapid is your trusted partner for accelerating innovation with precision and reliability.

Advantages at a glance

- 24/7 availability

- Best-cost production

- One contact person in China

- On-demand Manufacturing

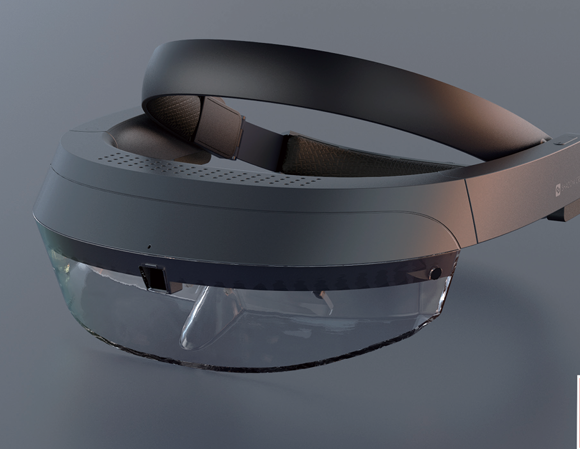

VR/AR Hardware

VR/AR Device Hardware

With the arrival of Web 3.0 and the development of integration, humanity has officially entered into the ear of the metaverse. Mixed reality technology in the metaverse has been applied across various industries. XR offers new approaches for a broad field of activity. With focus on prototype and low-volume production for AR/VR glasses and smart hardware (including AR, AR, and MR) device ODM and comprehensive application service solutions, aiming to create the “door” into the metaverse world.

Automotive

Automotive

The automotive industry is characterised by high quality requirements and short lead times. Innovation is always the top priority. Thanks to our many years of experience in the industry, we can reliably master these challenges.

Fast production of prototype components, best-cost production for precise model making, small series production in China for EV Sectors.

AI Smart Hardware

AI Smart technology

In addition to application safety and effectiveness, AI Smart technology places high and varied demands on parts production when it comes to developing a new device. We supply precise parts and hygienic surface finishes for consumer electronics prototyping (audio & video equipment, smart wearables) development.

Custom Your Rapid Prototyping

Got an idea in mind?

Turn your concept into a real product — fast and precisely.

Whether it’s creating functional prototypes or delivering small-batch production, we’re your direct rapid prototyping manufacturer.

Step 1 Initial communication about your prototyping needs

Step 2 Analyze your 3D drawings and present our proposal

Step 3 Prototype verification

Step 4 Fine-tuning and engineering adjustment

Step 5 Pre-production sample confirmation

Step 6 Small-batch production begins

Once samples are confirmed, we move forward with low-volume production — fast, flexible, and with full quality assurance.

Our production technologies

We work with any type of material and offer different production technologies such as: CNC machining, silicone moulds, injection moulding, 3D printing and sheet metal processing

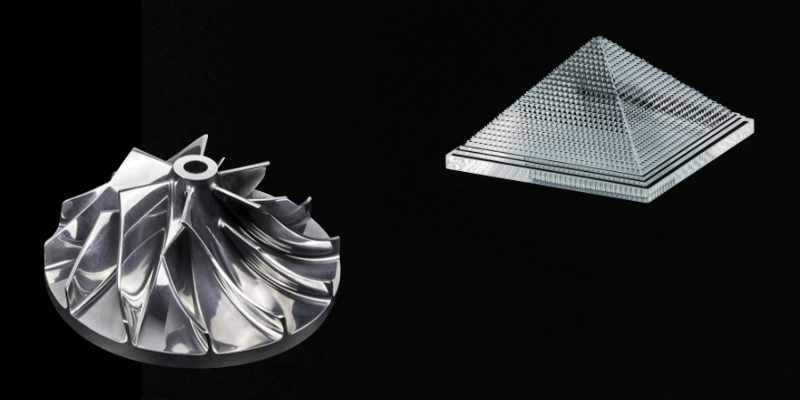

CNC machining: Maximum precision for complex geometries in plastic and metal up to a minimum milling radius of R 0.15 mm – R 0.10 mm

Vacuum casting: Vacuum casting with silicone moulds is ideal for small quantities, different colours, finishes and material properties.

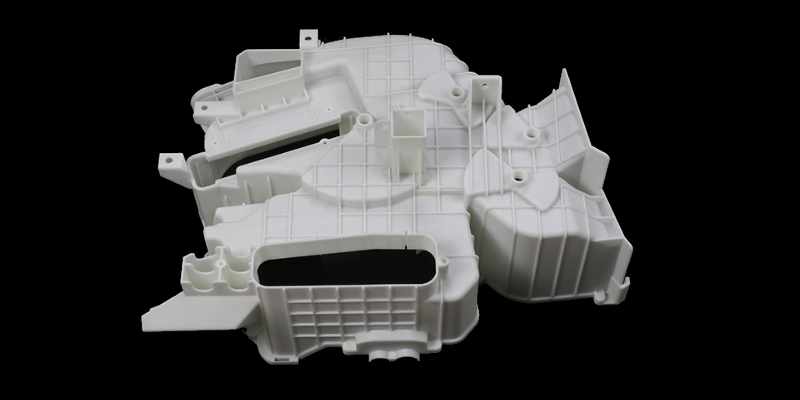

Additive manufacturing: Fast and precise production using additive manufacturing offers a great deal of freedom in the design and utilisation of pre-series components.

Injection moulding: We manufacture injection moulded parts for small series production, entirely according to individual component requirements.

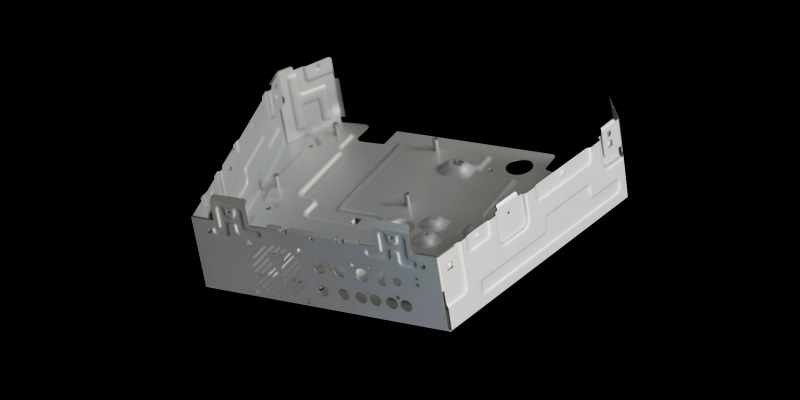

Sheet metal processing: We offer sheet metal processing from laser cutting and subsequent bending and post-processing

Surface finishing: With our wide range of colour material finish options, components or mockups are given the appearance of a series product.

Customer Market

Customer base is extensive, covering various fields such as consumer electronics, medical devices, and industrial manufacturing. The company has gained widespread market recognition by providing customized services to clients in different industries.

Discover new possibilities

Get in touch with us, describe your project and receive a quote and advice for the rapid production of your parts.

Further Capabilities Specifications: sales@golden-prototype.com

Contact us

Explore how Golden Rapid supports innovators across multiple industries — Our rapid prototyping and low-volume manufacturing services deliver precision, quality, and scalability for your next product.

Phone: +86 0592 373 1111

E-mail: sales@golden-prototype.com