Discover solutions

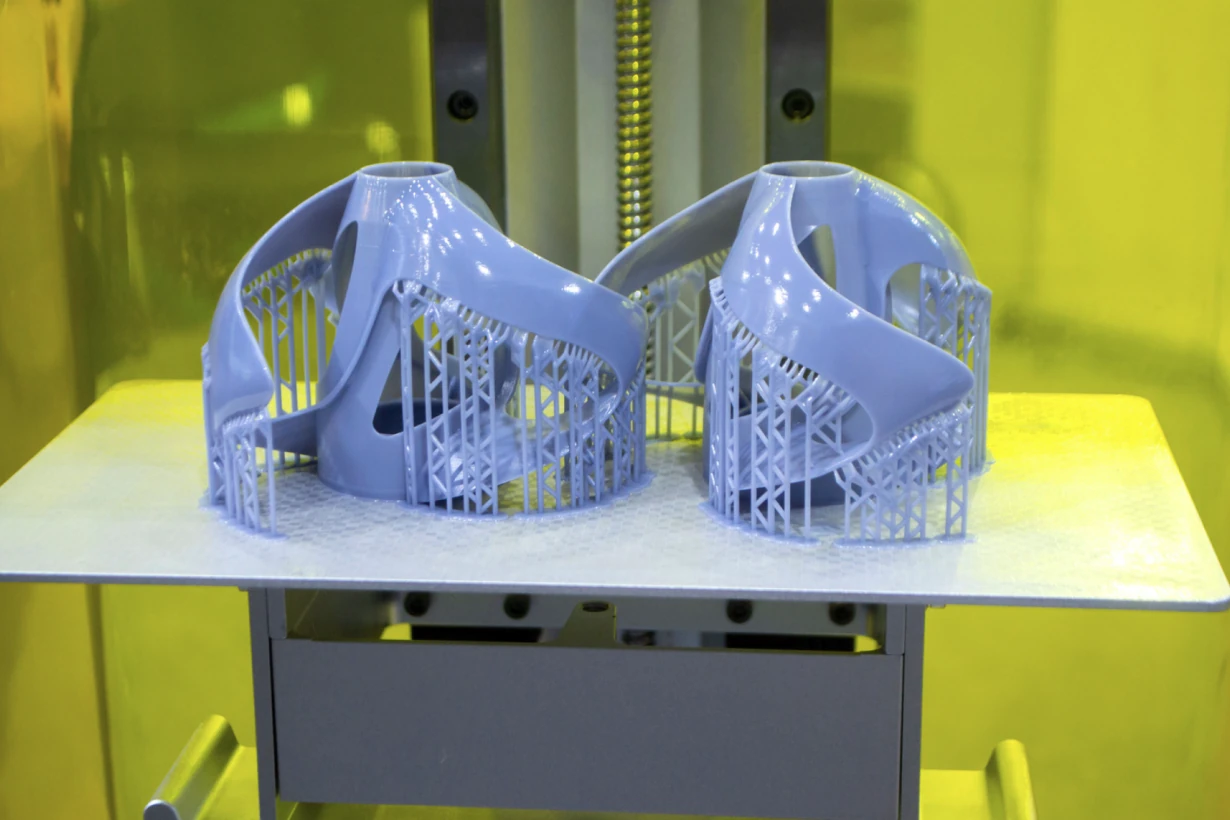

Bring Your Design to Life Instantly. Fast 3D printing for concept models and end-use parts. From SLA to SLS, we help engineers iterate faster and smarter.

With our one-stop shop for accurate, precise, custom 3D-printed parts at an affordable price. Upload your 3D CAD file to get a 3D printing quote and lead time within seconds. We print everything from single prototypes to thousands of production-grade parts.

Additive manufacturing

We use the latest additive manufacturing technology to build affordable, high-quality products in over 60 metals and plastics.

including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, Carbon DLS, metal binder jetting, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems and more.

3DP is an additive process that is identical to traditional 2D printing in almost every familiar way, from using dispensers to spray material and allowing for easy access to replace color cartridges. The most significant innovative difference is that a platform moves up and down along a 3rd axis, building up layers and bathing photopolymer resins in UV light to form solidified shapes (parts).Because traditional 2D printing is so familiar to us, 3D printing has become a popularized term used to include other sequential layering technologies such as SLA, SLS, FDM, and LOM.

With 3DP, Designers and Engineers can create incredible parts with Delicate Details & Tight Tolerances, suitable for developing next generation products such as Toys, Statues & Figures, Electronics & Appliances etc.

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

| Part Size | Xometry can accommodate 3D printing up to 24″ x 36″ x 36″ without the need to split and bond parts. |

| Minimum Feature Size | 0.030″ – 0.060″ is typical. |

| Minimum Wall Thickness | 0.020″ – 0.060″ is typical. |

| Clearance Between Features | At least 0.030″ |

Applications of 3D Printing

Rapid Prototyping

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Concept Models

The speed and versatility of custom 3d printed items lets product developers create physical snapshots of their designs through the iterative process.

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Discover new possibilities

- 1 Upload Your Design – Send a CAD design file to our team. We will assess the design for manufacturability and production requirements

- Receive a DFM Review – Our engineering team conducts a DFM analysis to improve manufacturability, quality, or cost-effectiveness.

- Confirm Your Quote – Confirm the quote which reflects the design, materials, and production requirements to initiate production.

- Begin Production– Production begins and you will be informed about the production progress or any issues.

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

We can convert CAD data formats so they are usable for production. Email:sales@golden-prototype.com

Contact us

Have a question? Get instant on time 3D printing service quotes on custom parts in dozens of plastic and metal materials. Contact us now!

Phone: +86 0592 373 1111

E-mail: sales@golden-prototype.com