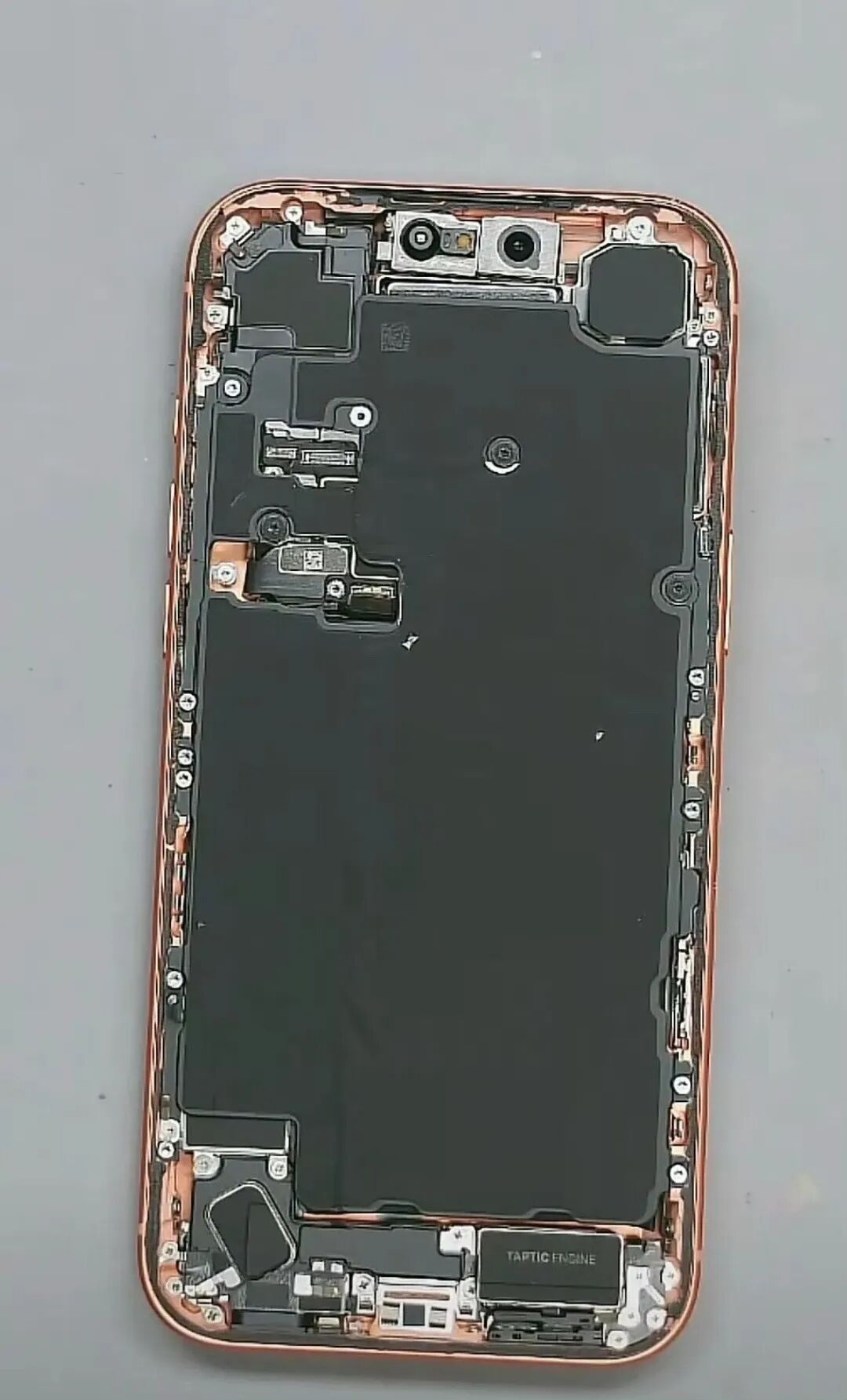

Structural, internal components

iPhone 17 series teardown, let’s appreciate Apple’s top-notch hardware design.

The iPhone 17 Pro uses the same layout as other phones with unibody aluminum bodies (GG Pixel 1/2). The mid-frame is detachable and screwed onto the unibody chassis. The 17 Pro’s heat spreader is integrated into the mid-frame, and the battery is fixed at the bottom.

This year, battery replacement is easier. The battery is now glued to the mid-frame but can be removed. When you unscrew the mid-frame, the battery comes out. The heat spreader is on the mid-frame, connecting the motherboard to the other parts of the phone.

integrated value Chain

Apple has integrated the entire mobile phone supply chain in mainland China, including CNC machining, operators, repairs, and after-sales service. prototype validation. rapid tooling. This has also been facilitated by Apple (through talent moving out from Apple’s contract factories); otherwise, how would so many people in China be familiar with Fanuc’s equipment and systems?

Apple’s production process from semi-finished products to finished products involves hundreds if not thousands of steps, with tolerances precise to 0.00mm. The process is very complex, and the appearance standards are very strict, which is why it’s more expensive.

Due to work reasons, I got a vivo XFold5 and a 16pm. Android feels more open-source; I can tweak it, and handling order files is smooth. Apple is more stable, especially the video clarity is really good in low-light conditions at night, but its battery life and signal are indeed disappointing. Once at an airport vending machine, I tried to buy water; the Apple phone had no signal and couldn’t scan the code, while the Android had no problem at all. A few others with Apple phones also struggled at the vending machine for a long time to no avail. Whether it’s Apple or Android, they each have their merits, just like some people love sweet while others love spicy…

Teardowns of the iPhone 17 series reveal Apple’s innovations in hardware design, particularly the Pro version, which adopts a brand-new cooling architecture. For the first time, the Pro series uses an aluminum alloy unibody chassis, with a detachable mid-frame that integrates a heat spreader, and the battery is attached to the bottom of the mid-frame for easier replacement. The cooling system uses a centrally placed aluminum alloy heat sink covering the motherboard, battery, and camera, combined with a laser-welded stainless steel VC heat spreader, significantly improving thermal efficiency. Compared to the previous generation, the Pro Max’s heat sink area reaches 8,000 mm², and the Pro is 6,500 mm², with battery capacities increased to 4,823 mAh and 3,988 mAh, respectively. These designs enable the Pro series to perform better in both power delivery and battery life while maintaining a lightweight body.

-

Apple Hardware Design: Redefining the Fusion of Technology and Aesthetics

Exploring the Innovative Path of Apple Hardware Design At the intersection of technology and art,…

-

iPhone 17 series tear down, let’s appreciate Apple’s top-notch hardware design

Structural, internal components iPhone 17 series teardown, let’s appreciate Apple’s top-notch hardware design. The iPhone…

-

Disassembly the iPhone 2G,first Gen

Structural, internal components This section provides an overview of the Front view, front view, rear…

-

Innovating solutions for tomorrow, today.

Golden Prototype is an industry leader providing experienced professional rapid prototyping services and solutions in…