Prototyping solutions

China-based factory serving Global Innovators directly

One-stop solution from design validation to pilot production

5–10 days standard turnaround for prototypes

Engineering support from experienced DFM specialists

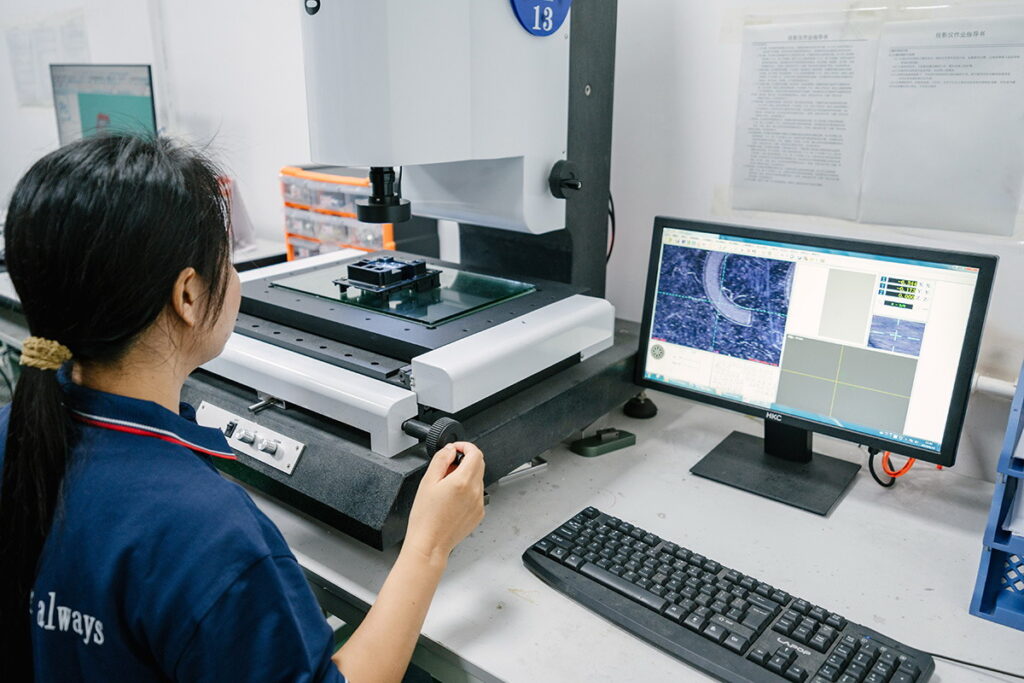

Quality Control

Coordinate measuring machine (CMM) SEREIN Croma

. VMS3020 Two-dimensional measurement

. Granite inspection table

. Digital Calipers, 0-600 (mm)

. Full range of pin gage, 0.5-12 (mm)

. Outside micrometers, 0-25-75-100-125-150 (mm)

. Surface roughness tester, hardness tester

Rapid Prototyping

Advanced 3D printing, PIM Molding services for rapid prototyping and product development.

Turn your concepts into functional prototypes in days, not weeks.

- Validate designs quickly before mass production

- Combine CNC machining, 3D printing, and vacuum casting

- Perfect for product demos, investor presentations, and testing

Bridge the gap between prototype and volume production.

- Low-cost, fast-turnaround tooling for plastics and metals

- Small-batch injection molding for ABS, PC, TPU, and other materials

- Scalable solution for pilot runs and market testing

Low Volume Production

Low volume production options including vacuum casting and plastic injection molding, CNC machining.

Manufacturing designed for small to medium batch sizes.

Consistently high quality at competitive prices

Pilot runs of 100–5,000 parts

Prototyping, Pre-Production, and Manufacturing – we support your full development cycle.

Supply chain support for scaling up to mass production

Sub-assembly and QC before shipment

Engineering feedback for manufacturability improvements

Discover new possibilities

Upload your design, receive a DFM review, confirm your quote, and start production. Get updates at every step for quality, cost-effective

- 1 Upload Your Design – Send a CAD design file to our team. We will assess the design for manufacturability and production requirements

- Receive a DFM Review – Our engineering team conducts a DFM analysis to improve manufacturability, quality, or cost-effectiveness.

- Confirm Your Quote – Confirm the quote which reflects the design, materials, and production requirements to initiate production.

- Begin Production– Production begins and you will be informed about the production progress or any issues.

Get in touch with us, describe your project and receive a quote and advice for the rapid production of your parts.Email:sales@golden-prototype.com

Contact us

Ready to start your next prototype? Get a quote today and experience fast, precise, and reliable on-demand manufacturing. Contact us now!

Phone: +86 0592 373 1111

E-mail: sales@golden-prototype.com