Make Every Detail Shine

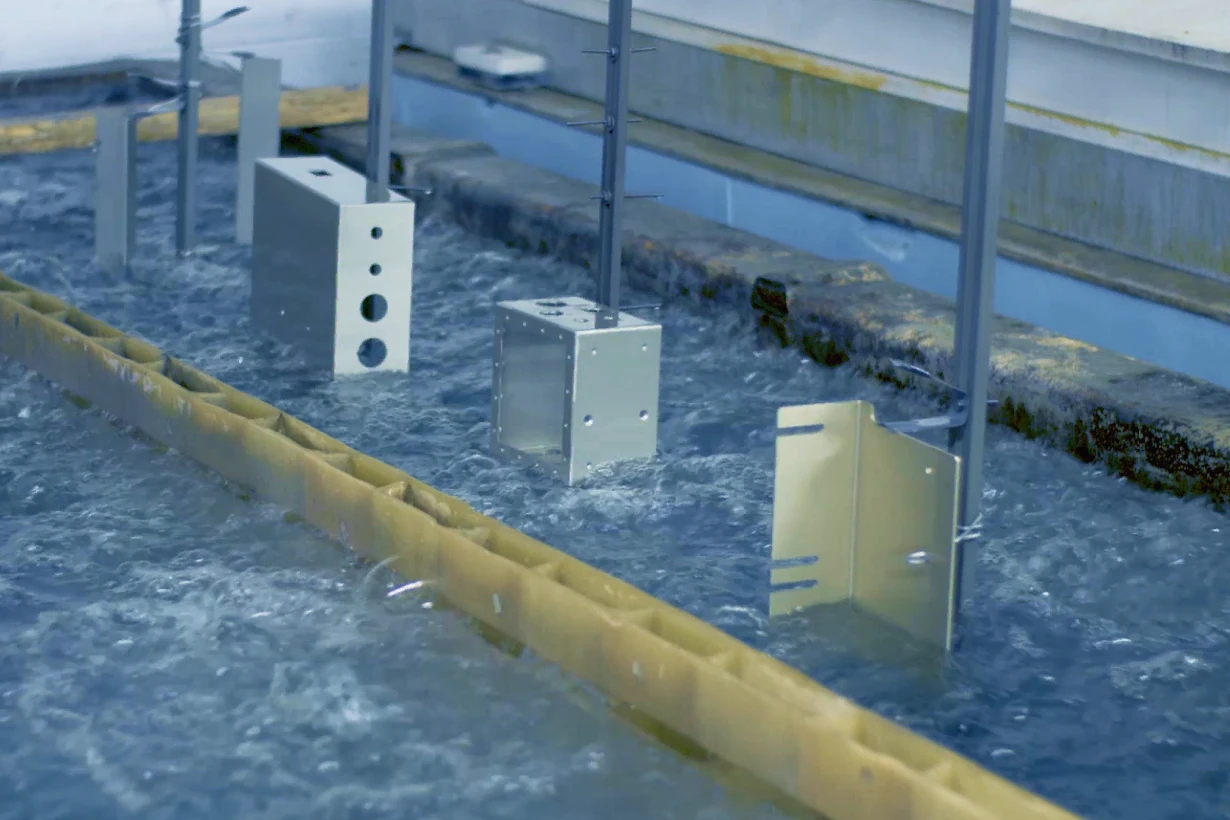

Comprehensive finishing services for metal and plastic prototypes — perfect balance of aesthetics, protection, and performance.

Surface Finish & Post Operation

Bead Blasting, Meshed, Brushed & Hair Line Texture

Hand, Vapor, Electro Polishing

Silk, Pad, Direct Digital Printing

Matte, Gloss, Soft Touch Painting

UV & AF Coating

Anodizing & Alodine

Electroplating

Passivation

Teflon, Powder & DLC (Diamond Like Carbon) Coating

Chemical/Laser Etching

Laser Cutting/Marking

Black Oxidation

PVD (Physical Vapor Deposition)

Post Inserting , Ultra Sonic Welding

We offer finishing services for most of our manufacturing processes, including CNC machining, sheet metal Fabrication, 3D printing, injection molding, urethane casting, and more!

Offers many standard finishing options which instantly price online. For further customization, you can specify multiple finishes per part; we are your one-stop shop. Learn more about each finish we offer and see examples in the sections below.

Popular Finishes for Metal

Standard

Part is cleaned and deburred. No surface finishes are applied

Type II Anodize

Type II anodize provides increased corrosion resistance and can be used as a base for paint and other finishes. Thickness ranges from .0002”-.0012”. Will conform to MIL-A-8625/MIL-PRF-8625 Type II, Class 2.

Color anodizing involves using dyes to affect the part’s surface color. Anodized colors cannot be matched to specific Pantone or RAL colors. Type II coatings are susceptible to wear and may bleach or fade under prolonged direct sunlight.

Type III Hardcoat Anodize

Type III hardcoat anodize produces a thicker layer of standard anodizing, making it more durable and wear-resistant. It can be used as a base for paint and other finishes. Colors tend to come out slightly dark due to thickness. Anodized colors cannot be matched to specific Pantone or RAL colors. Thickness is generally 0.002” and will conform to MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2.

Although unpigmented, a clear hardcoat anodize finish will darken the part surface due to the higher thickness of the coating compared to standard anodizing. Depending on various factors, the natural color can vary from light to darker gray or brown.

Chromate Conversion (Chem-Film)

Chromate conversion coatings, also known as chem-film, enhance corrosion resistance and conductivity properties and can be used as a base for paint. Chem-film coatings add very little thickness, about 0.00001”-0.00004”. Chem-film will conform to MIL-DTL-5541, TYPE I/II CLASS 1A or CLASS 3 as specified. If other specifications, such as MIL-DTL-81706, are required, they should be specified in a supplied drawing.

Type I chromate conversion coatings contain hexavalent chromium, which causes the coating to appear gold or brown in color typically. Type II lacks hexavalent chromium, thus the coating will appear clear and not affect surface coloration.

Powder Coating

Provides a continuous, protective color finish on parts using evenly applied, heat-cured paint. Thickness is usually .006”-.012” and conforms to ASTM D7803 and various MIL and FDE specifications. Various colors and sheens can be chosen.

Other Metal Finishes We Offer

Black Oxide Electropolishing Heat Treatment Passivation Electroless Nickel Plating Gold Plating Silver Plating Zinc Plating Media Tumbled Powder Coating Wet Painting Other Custom Finishing

Popular 3D Printing Finishes

Vapor Smoothing

Vapor smoothing creates a uniform, sealed surface with a semi-gloss appearance. It can be combined with our color dyeing option.

A standard offering for:

Selective Laser Sintering (SLS)

HP Multi Jet Fusion (MJF)

Color Dyeing

Parts are submerged in a dye solution that penetrates roughly ~0.010” into the surface, altering the surface’s color. Coloration may vary slightly from batch to batch.

A standard offering for:

Selective Laser Sintering (SLS)

HP Multi Jet Fusion (MJF) — Black Only

Nickel Plating

Standard finish with a secondary copper + nickel plating process, adding a 0.004″-0.006″ nickel coating. Nickel plating adds durability, stiffness, and wear resistance but is not considered cosmetic. The finish is rough nickel.

A standard offering for:

Selective Laser Sintering (SLS)

Plastic Injection Molding Finishes

Our standard mold finishes include the following:

- Society of Plastics Industry (SPI) Mold Finishes

- Mold-Tech

- VDI

Urethane and Silicone Casting Finishes

Matte/Frosted

A standard finish where the master pattern is lightly processed to produce a matte or frosted appearance on opaque and translucent materials accordingly.

Semi-Gloss

The master pattern receives additional processing to create a smoother surface which produces a semi-gloss surface on the cast parts.

High-Gloss

The master pattern is processed extensively to polish the surface to create a very smooth surface that results in glossy or clear parts when cast.

Textured

A selection of SPI and Mold-Tech mold finishes which mimic those of injection molded parts.

Custom

we can provide additional processing and finishes, such as hardware installation, overmolding, and painting to meet your needs. Specify a custom finish for a manual review.

From clear acrylic panels to thick tool steel, upper offers a one-stop-shop solution for any project with instant quotes, tight tolerance capabilities, and a wide selection of materials, including:

- Metals

- Plastics

- Wood

- Composites

- Foams

- Rubber & Gaskets

Discover new possibilities

Golden , allows product developers to work with skilled experienced Finishing Technicians that specialize in making Visual Design Models, Appearance Models, ID Concept Models, and Form Studies.

At Golden, we follow International Specifications for color: PANTONE, RAL, TOYO, DIC, MUNSELL, and NCS, and for texture (Ra scale): MT Mold Tech from the USA, VDI from Germany, and YS Yick Sang from SAR H.K.

Provide paint coatings in any sheen: High Gloss, Semi-Gloss, Low Gloss, including Soft Feel coatings, and custom mixed colors matched under color correct lighting to perfect CMF specification.

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

We can convert CAD data formats so they are usable for production. Email:sales@golden-prototype.com

Contact us

Have a question? Get in touch with us, describe your project and receive a quote and advice for the rapid production of your parts. Contact us now!

Phone: +86 0592 373 1111

E-mail: sales@golden-prototype.com