Discover Cost-Effective Small Batch Prototyping solutions

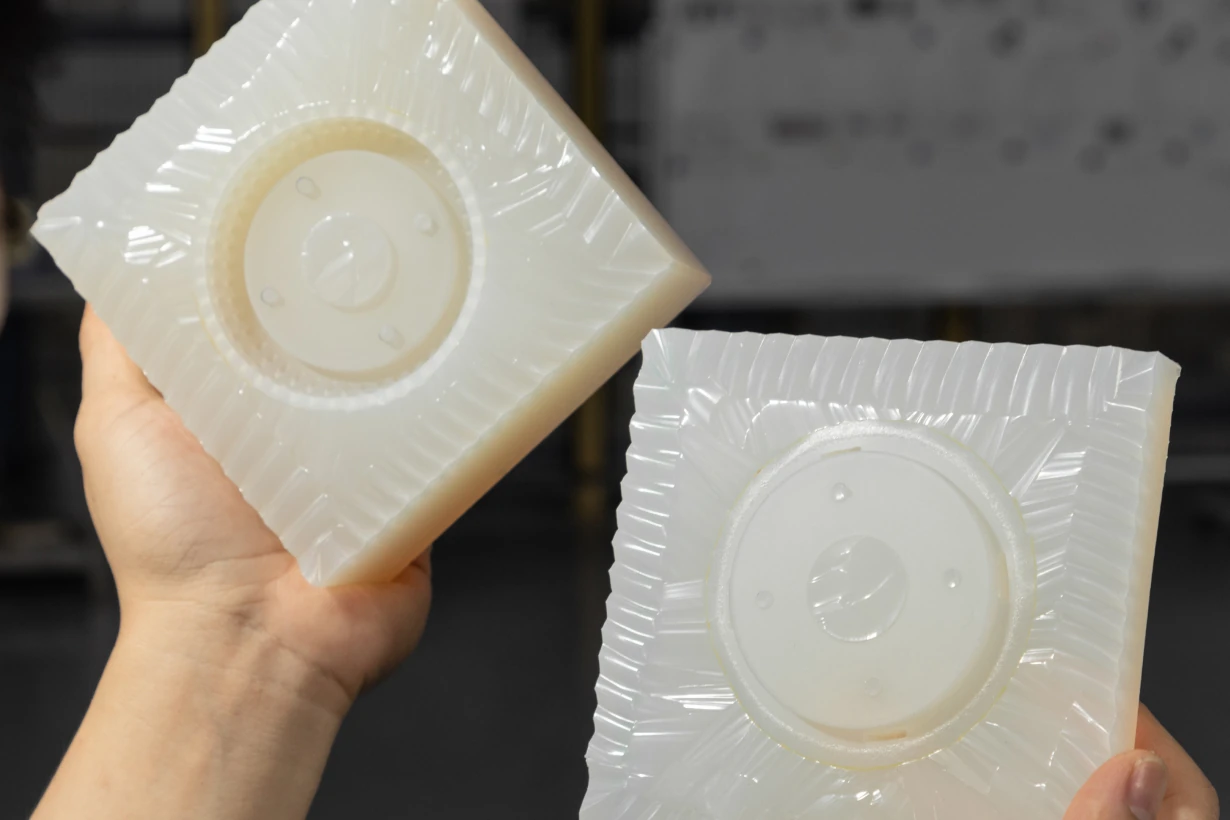

Urethane casting bridges the gap between 3D printing and injection molding — flexible, durable, and ideal for design validation.

Compression Molding For Durable Rubber, Silicone, And Composite Parts. Provides Superior Resistance To Wear And Environmental Stress.

→ Ideal For Gaskets, Vibration Dampers, And Industrial-Grade Components.

Applications: Gaskets, Medical Pads, Insulation

Material – Manufacturers, Hardness

LSR (Liquid Silicone Rubber) : KCC, Shinetsu (10 ~ 90A)

HCR (High Consistency Silicone Rubber) : KCC, Shinetsu, Dow Corning (10~90A)

Medical Silicone : ISO10993, USP Class VI (40~70A), Nusil (Wacker), Dow Coring

Fluor Silicone : Shinetsu (20~80A)

NBR ((Acrylo)Nitrile Butadiene Rubber) : Kumho Petrochemical (40~90A)

EPDM (Ethylene Propylene Diene Monomer) : KUMHO POLYCHEM (40A~90A)

NR (Natural Rubber) : SP Chemical (40~90A)

SBR (Styrene Butadiene Rubber) : SP Chemical (40~90A)

CR (Chloroprene Rubber) : SP Chemical (40~90A)

H-NBR (Hydrogenated-Nitrile Butadiene Rubber) : SP Chemical (50~90A)

PU (Poly Urethane) : SP Chemical (60~90A)

Medical Silicone, Fluor Silicone : MOQ 20Kg

Quick Turn(Mobile Phone Size)

- Simple 5-6 Day

- Normal 8 Day

- Complex 11 Day

Mix. Size & Color

Max. Size : 550X900x400mm

Pantone Color Code Or Chip Is Mandatory

NBR/EPDM – MOQ 100Kg And All Others Will Be

10Kg NBR Clear Is Not Feasible For Coloring

Cast urethane parts are ideal when color, surface quality, and toughness are required for quantities from one to one hundred. Urethane molding is a perfect alternative for insert molding or over molding in low volumes with diverse material choices. Polyurethane or silicone casting can bridge production between a 3D printed rapid prototype and an injection molding with a balance of quality, cost, and time. Urethane cast parts can be clear, color-matched, painted (including EMI shielding), installed with inserts, and custom finished.

Urethane Casting

Whether you work in the aerospace, automotive, healthcare or electronics industries, at Golden we develop solutions that are customised to your specific requirements. Urethane casting provides end-use, rigid plastic, rubber, and silicone parts with production-level quality. As a leader in urethane casting services, with domestic (China-based) and international economy options to fit your timeline and budget; pricing includes tariffs for prototypes. Urethane gives professional results for low-volume production using a soft-tooling approach, utilizing 3D-printed master patterns and RTV silicone molds.

Urethane Casting Materials

Polyurethane is a widely used thermoset material grouping known for its strength, durability, abrasion resistance, and versatility. Different urethanes can mimic the properties of many common thermoplastics. For example, a stiff urethane cast part is “polycarbonate-like,” and a more flexible plastic may be “polypropylene-like.” We group our urethane materials into general categories to help you make quicker decisions and get the best performance on your project. The list below describes the categories of materials and technical examples when selecting polyurethanes.

Cast Urethane Materials

| Material Name | Shore Hardness | Description | Technical Information | Data Sheets |

|---|---|---|---|---|

| General Purpose | Shore D 76-80 | An impact-resistant Shore 78D material used for a variety of purposes, from enclosure housings to concept models. This material exhibits ABS-like properties. | TC-878, TC-852, or equivalent | General Purpose Data Sheet |

| Rigid Clear | Shore D 80 | A versatile, Shore D 80, clear polyurethane. A matte finish will give a frosted appearance and a higher gloss will increase its transparency. | Poly-Optic 1410 or equivalent | Rigid Clear Data Sheet |

| ABS-Like, FR | Shore D 78-82 | A tough Shore 80D flame retardant material that is UL Listed with a flammability rating at 1/16″ (1.6 mm). | TC-891-FR or equivalent | ABS-Like, FR Data Sheet |

| Polypropylene-Like | Shore D 65-75 | A tough and abrasion-resistant flexible urethane with polypropylene-like ductility. | TC-872, HP-2270D, or equivalent | Polypropylene-Like Data Sheet |

| Polycarbonate-Like | Shore D 82-86 | A stiff, high impact, high HDT, material with a wide variety of uses. Simulates polycarbonate (non-clear), Shore 84D. | TC-854 or equivalent | Polycarbonate-Like Data Sheet |

| Glass-Filled Nylon-Like | Shore D 85 | A stiff, USP Class VI, high-performance urethane with high impact strength and a HDT of 190°F (88°C). | PT8902 or PT8952 (FR) | Glass-Filled Nylon-Like Data Sheet |

| Rubber-Like Polyurethane | Shore A 25-95 | A Shore A elastomer with a high elongation to break. | F-130 to F-190 or equivalent | Rubber-Like Polyurethane Data Sheet |

| Clear Rubber-Like Polyurethane | Shore A 40-95 | A colorless Shore A elastomer with a high elongation to break. Matte finish will give a frosted appearance, and higher gloss will increase its transparency. | WC-540 to WC-595 or equivalent | Clear Rubber-Like Polyurethane Data Sheet |

Note: Equivalent materials may be used based on availability.

Applications of Urethane Casting

Low-Volume Production

Urethane cast parts are perfect for low-quantity production—when volumes do not justify investment in injection mold tooling—as well as for first run production parts, which can be completed weeks before production tooling is ready.

Advanced Prototyping

The urethane casting process and relatively inexpensive tooling involved makes it easy and economical to make any necessary design changes. Additionally, different materials can be used with the same mold, making it possible to test designs with a variety of materials

Market Testing

End-user functionality and a high-quality finish makes urethane cast parts ideal for consumer testing, user evaluation and concept models. Using the cast urethane process means that changes can be incorporated quickly for either further testing or market launch.

Tolerances Vacuum casting of polyurethane parts is primarily dependent upon the tolerance of the master model (see SLS tolerances), then a tolerance of +/- 0.15% is applied as a general rule. This varies depending upon weak geometry. To ensure the accuracy of Golden Prototype’s polyurethane parts, we usually machine a fixture for post-heat-treatment. This ensures that the part does not shrink upon heat treatment.

Discover new possibilities

Upload your design, receive a DFM review, confirm your quote, and start production. Get updates at every step for quality, cost-effective

- 1 Upload Your Design – Send a CAD design file to our team. We will assess the design for manufacturability and production requirements

- Receive a DFM Review – Our engineering team conducts a DFM analysis to improve manufacturability, quality, or cost-effectiveness.

- Confirm Your Quote – Confirm the quote which reflects the design, materials, and production requirements to initiate production.

- Begin Production– Production begins and you will be informed about the production progress or any issues.

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

We can convert CAD data formats so they are usable for production. Email:sales@golden-prototype.com

Contact us

Have a question? Get in touch with us, describe your project and receive a quote and advice for the rapid production of your parts. Contact us now!

Phone: +86 0592 373 1111

E-mail: sales@golden-prototype.com